research

R&D CENTER

-

Research & Development

Leading R&D Center -

Mecotec Titanium holds differentiated production technologies in the global industrial market, and produces the best products through continuous R&D. In addition, as a leading company in the titanium and special metals industries, we always take on new challenges and innovate ourselves.

Characteristics of Titanium

-

Titanium

-

Light metal

Light metal

Titanium’s specific gravity: 4.51

Titanium has a weight halfway between that of aluminum and iron, 60% the weight of stainless steel and 50% the weight of copper. Titanium is used as a material in the military field, including aerospace, aircraft material, and body armor, based on its excellent specific strength (strength to specific gravity).DATA

-

High tension

High tension

Titanium is twice as strong as iron and three times as strong as aluminum. Pure titanium has a similar strength to stainless steel, but alloy titanium is twice as strong.

DATA

-

Thermal resistance

Thermal resistance

The melting point of titanium is 1668 ℃, which is relatively high compared to other metals, such as iron (1530℃), copper (1080℃), and aluminum (660℃). Titanium maintains its properties up to 500℃ through strong heat resistance.

DATA

-

Biocompatiblilty

Biocompatiblilty

Titanium is harmless to the human body and has the biocompatibility to bond with human bones, so it is a metal that has been in the spotlight in various medical fields such as orthopedics and dentistry.

DATA

-

Erosion resistance

Erosion resistance

Titanium has excellent corrosion resistance and does not rust even in seawater and strong chemicals, so it is used in various heat exchangers and piping in the chemical industry.

DATA

Light metal data

Features of each type

-

-

c.p

TITANIUM -

gr.1 High elongation, good formability, and easy to process

gr.2 Most widely used due to its light weight and excellent mechanical properties

gr.3 Excellent mechanical properties and good elasticity allow it to be used as a spring

gr.4 Due to its high elasticity, it is used for spring applications

-

TITANIUM

alloy -

gr.5 Due to its high elasticity, it is used for spring applications

gr.7 It is a 0.12-0.25% palladium alloy with particularly excellent corrosion resistance and the same mechanical properties as Grade 2

gr.9 Ti 3Al2.5V alloy with very good mechanical strength and good elasticity

gr.11 It is a 0.12-0.25% palladium alloy with particularly excellent corrosion resistance and the same mechanical properties as Grade 1

gr.12 Ti 0.3Mo0.8Ni alloy with better mechanical strength than Grade 2

-

-

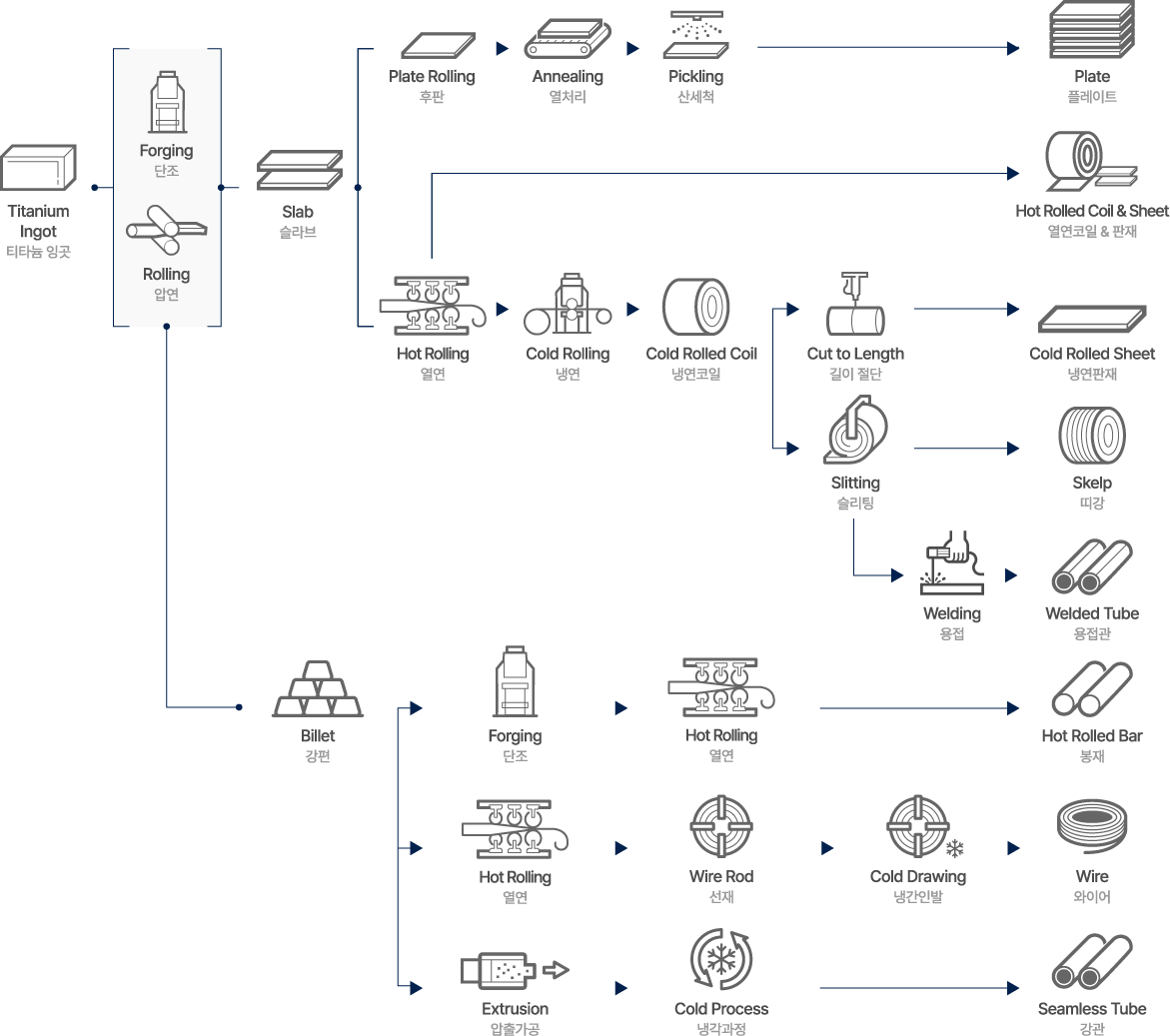

Production process

var process

(VAR: Vaccum Arc Remelting)

-

Ti Sponge

-

Pressing

-

Welding

-

Melting

-

Titanium Ingot

- Hot rolling

- Cold rolling

Products