products

Surface Treatment Equipment & Materials

-

Equipment for Metal Surface Finishing

With our proprietary metal surface treatment technology,

we can increase the corrosion and abrasion resistance

of easily corrosive metals prone to wear. -

Products

Mecotec Titaniumopens a bright future with our technology

-

-

-

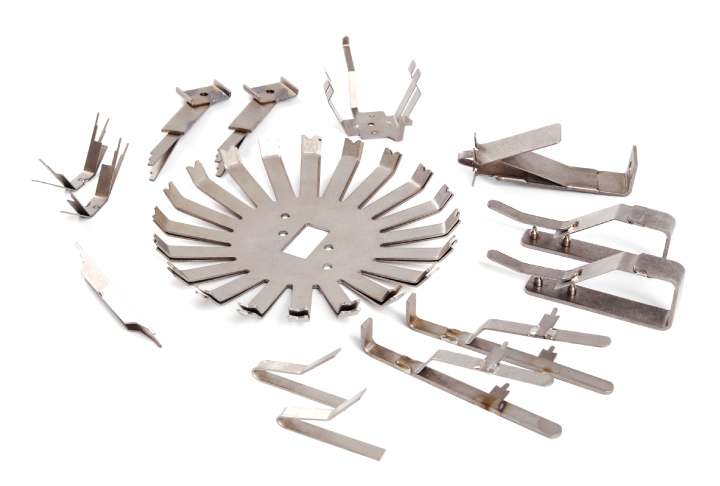

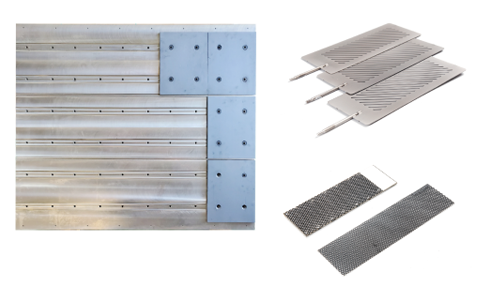

Titanium Rack

Titanium rack

Titanium rack is used in the aluminum anodizing and stainless steel electropolishing process. The clip part has excellent circular recovery by applying a highly elastic material, and it firmly supports and connects the electrode and the object to ensure a smooth electricity flow.

-

-

-

-

target

Target Materials : Ti, Zr, Cr, W, Mo

Targets are materials for thin film formation in the ion plating and vacuum deposition process that improves the corrosion resistance, abrasion resistance, and durability of various industrial tools, molds, and semiconductor parts. Purity is selected according to the use, and targets are produced by precision processing in various forms.

-

-

-

-

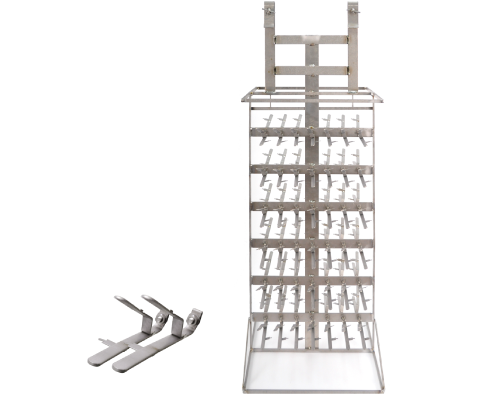

Titanium Basket

Titanium baskets

Titanium baskets are products that plate nickel, zinc, copper, and tin that are ionized at the anode in the precision plating process of semiconductor lead-frame and PCB. They use pure titanium, so they have high corrosion resistance and low specific gravity relative to their high strength, indicating strong durability. Various types of products can be manufactured according to usability.

-

-

-

-

DSA -Dimensional Stable Anode

Insoluble electrodes Iridium oxide (IrO2), ruthenium (RuO2), platinum (Pt)

DSA is manufactured by coating iridium oxide on titanium or electroplating platinum. When it is made by coating titanium, oxygen and chlorine are generated due to the electrical properties of titanium, maximizing voltage and electrical energy efficiency and enhancing corrosion resistance. An additional advantage is that electrolyte contamination can be minimized when using the anode.

-

-

-

-

Bus-Bar

Bus-Bar (Ti-Cu)

Busbars are essential components in the power grid because they suppress power loss and conduct power. They are produced by the simultaneous drawing, extrusion, explosion, and pressure welding of copper and titanium, and the production minimizes defects because there are no byproducts or corrosives.

-